EDGE TRIMMING SYSTEM

Edge trimming systems designed for the precise, simple, and safe adjustment of trim nozzles on modern, fast running paper machines.

The systems have been designed to meet all the needs of this application and enable the operator to adjust the nozzles optimally and safely. The mounting and dismounting on the base plate is simple and safe.

The complete unit can be placed on the base plate, adjusted or removed in seconds with just a few moves.

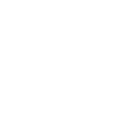

3.1 EDGE TRIMMING SYSTEM ETU-NO1

- edge trimming system made from stainless steel AISI 316Ti

- with built-in screw drive for manual movement in cross machine direction (CMD)

- solid and extremely durable

- equipped with pressure adjusting unit and rapid exchange filter unit

- optionally with remote nozzle setting device

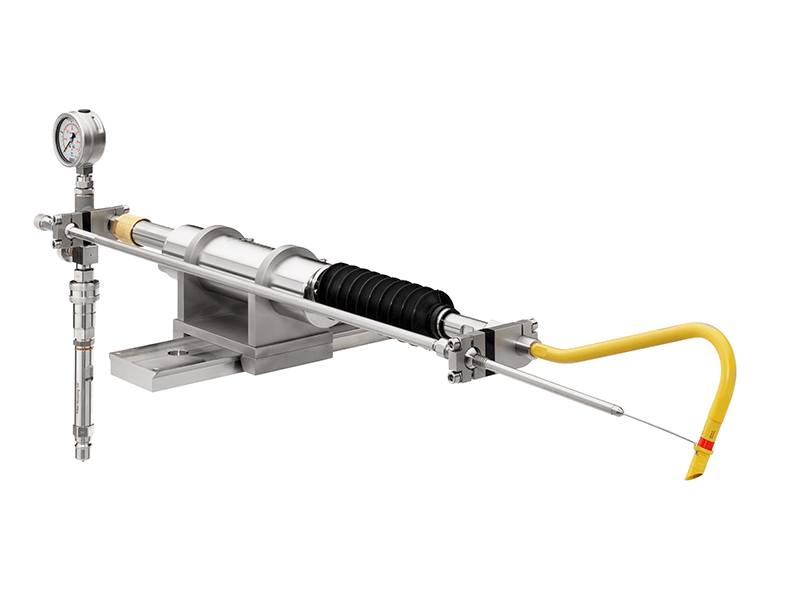

3.2 EDGE TRIMMING SYSTEM ETU-NO2

- edge trimming system ‘light’ made from stainless steel AISI 316Ti

- compact, stable and extremely durable

- perfect for side-by-side installation and operation of two or three nozzles in line

- equipped with pressure adjusting unit and quick exchange filter unit

- optionally with remote nozzle setting device

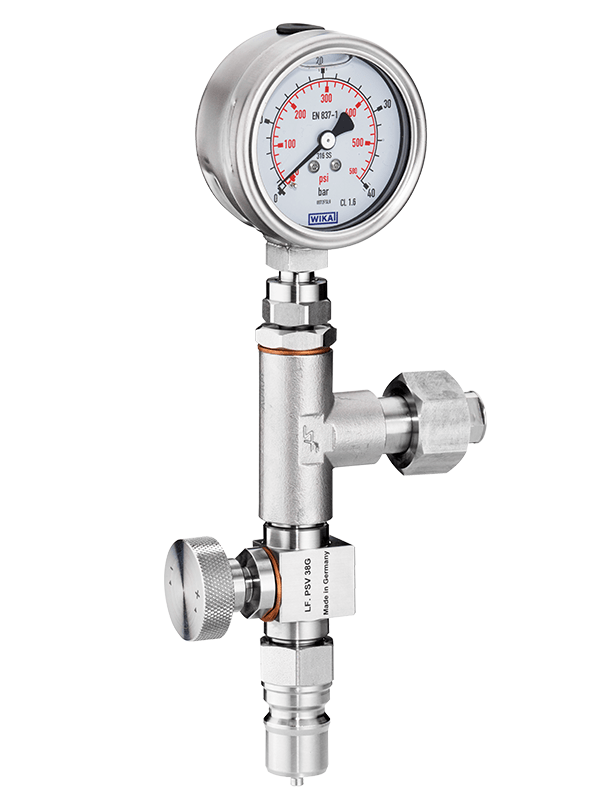

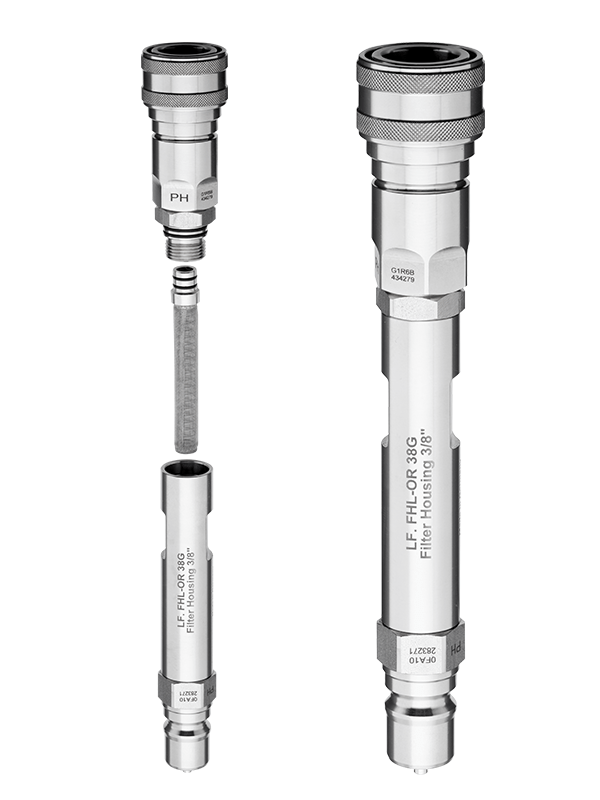

3.3 PAU PRESSURE ADJUSTING UNIT

- with 360° rotating pressure gauge

- display bar/PSI

- max. pressure 40 bar

- featuring the especially developed FABINY pressure setting valve

- with capnut and taper and seal for easy installation to the Fabiny trimming systems type ETU-NO1 and ETU-NO2

- with quick connector to assemble the Rapid Exchange Filter Assembly